Those who are in the business of making jams and preserves require high operating efficiency, especially for manufacturers in the food industry. Having his/she high-quality jam filling machine into operation provides more repetition, accuracy and increases the quality of the product. In this way, they deliver a lot of valuable results for the production of jam, which will be illustrated below.

Much Quicker Production Time

The most obvious reasons to use a jam filling machine is that the speeds increase greatly in comparison to the manual method. This is quite a labor-intensive process susceptible to errors and rough, non-uniform results from the manual filling method commonly used so far. In contrast, a modern jam filling machine can handle hundreds to thousands of jars an hour. For example, the most advanced auto-fill machines can fill more than 2,000 jars per hour, a rate that would be prohibitive in any manual process. Higher throughput, which means you will be able to meet larger orders faster with ease.

Improved Accuracy and Quality

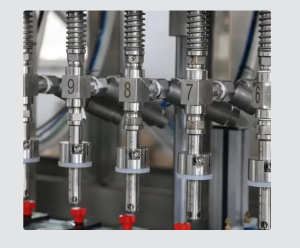

Filling each jar without fail with the exact amount of jam is necessary for both the products quality and legal standards. Jam filling lines feature precision metering and dispensing systems, to fill each jar to the same weight while minimizing give-away. This consistency of service helps to ensure that are customers receive what they expect in terms of quality and quantity in every jar they buy from you.

Reduction in Labor Costs

The biggest cost in manufacturing is labor, but the process of filling the jam can be automated which helps to spare the need for manual labor. When using a dependable jam filling machine, manufacturers can dedicate their human resources to other important aspects of the business, like quality control (either in production or the product), packaging, or customer service. This not only saves the employers money but also decreases the amount of physical work that has to be done by the employees, as well as create a lower chance of employees injure themselves because of repetitive tasks.

Improved Workplace Safety

These automated machines save and protect the workers from remotely controlling the machinery and containers thereby preventing them from any accidents or injuries. In addition to this, newer filling systems are built with tools for safety available like emergency stops, guards, sensors and many more that contribute to a safe working environment. These safety improvements not only help in keeping employees safer while on the job, but they also help to prevent costly downtime and liability issues.

Versatility in Production

While most current top jam filling machines are able to work with a variety of jams, a lot of them offer a level of flexibility that stretches beyond merely being able to manipulate different types of jams. They can be modified to fit different container sizes and shapes, and can read products with varying viscosities or those with pieces of fruit. This flexibility allows you to quickly respond to changing product lines or consumer preferences and use a single piece of equipment across different products, driving capital utilization.

Sustainability and waste prevention

Most automated filling machines are typically far more effective in the way they use the materials, thereby reducing cardboard wastages massively. Less spillage (precise filling reduces overflows/spills), faster running speed (less time filling per unit of product processed) reduces the amount of energy consumption per unit of product processed. This increased efficiency in resource usage makes these an invaluable improvement for eco-conscious companies looking to improve their environmental footprint.

So, with all the other benefits, you get the joy of efficiency and enhanced production with a jam filling machine integrated into your production. These machines are crucial to the ability of jam manufacturers to expand their production capabilities, improve the quality of their products and efficiently cater to the changing needs of the market.