Custom Metal PrototypesOverview

Laser Cutting Metal PrototypesLaser cutting is a vital step in metal part and component fabrication using custom metal prototypes because of its ability to deliver the precision necessary for sophisticated design. This technique utilises assorted techniques, turning raw materials into finished prototypes. The method used varies, depending on the complexity of the design, the properties the final product must have, how many units needed.

Metal Prototyping Key Techniques

CNC Machining CNC (Computer Numerical Control) machining is one of the common methods for creating custom metal prototypes. This manufacturing process which eliminates metal to provide the end product is carried out with the help of Computer-controlled Machine Tools. CNC machining has a high level of accuracy, usually about 0.005 inches (0.127 mm), making it suitable for fine components.

Metal 3D Printing: Metal 3D printing, also referred to as additive manufacturing, creates the parts by adding material layer by layer using metals including stainless steel, titanium, and aluminum. This technique is particularly well-suited for fabrication of complex shapes that are cumbersome or impossible to produce using conventional machining. Metal 3D Printing is considerably faster now than it was a few years or so earlier and in a matter of hours you can get parts manufactured

Sheet metal fabrication : It is the process of sheet metal we can be cut and bent in shapes and structure. Smelting, punching, bending, laser cutting, are usually used techniques Sheet Metal Fabrication: Sheet metal fabrication is an affordable method to manufacture metal parts in less quantity, and is best-suited for the larger components.

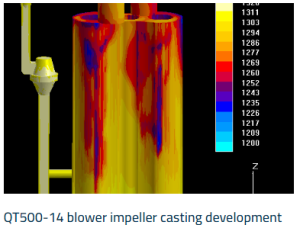

Investment Casting: Investment casting is a type of prototyping used when every detailed and intricate design is vital. During it a wax model of the part is made and this wax model is placed into ceramic. After the ceramic dries, the wax is melted out of the mold and liquid metal is poured into the mold. Once the metal has been allowed to solidify, the ceramic shell is removed, and the final part is revealed.

Benefits of Custom Metal Prototypes Fabrication

Speed — Rapid prototyping methods ( e.g., CNC machining and metal 3D printing) allow companies to produce prototypes in a short time, which helps create faster developing market fit designs.

Accuracy and Personalization: When you are making prototypes for metals especially for industries like aerospace and medical tools where the elements can be met with aviation standards and have to maintain a certain standard. With custom metal prototypes fabrication, you get sizeable customization that can take abnormal shapes and complex design specifics state of the art accuracy.

Modern Rapid Prototyping: Quick and Lean Prototyping became fast and lean. For instance, additive manufacturing can involve material used only where required, reducing waste and saving on costs for material versus traditional subtractive techniques, such as machining.

Use Cases Across Industries

To carry out the prototyping process effectively, various industries, such as automotive, electronics, etc., make use of custom metal prototypes which help them to assess their designs and bridge the gap between product modelling and mass production. So, for instance in the automotive sector, metal prototypes are used to trial engine parts, gearbox assemblies and the like, fine tuning them before the final production effort.

Looking Forward

As technology advances, so does the fabrication of custom metal prototypes, that becomes both easier to produce and more efficient. There is a great advantage in how companies adept at using them can streamline their innovation cycles, cut their time, to market and achieve a better product quality. These are few points that can speak about the virtuosity of Ryan's work however to delve deeper on to the benefits of these custom Metal prototypes fabrication, log on to Custom Metal Prototypes Fabrication to know how these can be used and could benefit your projects.